- Services

H3 offers an ever-evolving and encompassing range of services ↳

Car Park RefurbishmentExtending the life of your parking structure ↳

Structural Repairs & ProtectionConcrete repairs & corrosion management ↳

Structural WaterproofingAdvanced structural waterproofing solutions ↳

Resin Floors & CoatingDurable, safe, easy-to-clean flooring solutions ↳

EVHard-wearing line and bay marking ↳

ConsultancyPrecise care & attention for you project ↳

Specialist SurveysIdentifying problems to avoid bigger issues ↳

Aftercare/Asset ManagementPreserving your asset for the long term ↳

Movement/Expansion JointsHandling temperature, structural & traffic shifts ↳

Flooring SolutionsTailored carpet & vinyl flooring solutions ↳

SwiftPatchOur Rapid Repair Service

- SwiftPatch

- Case Studies

Examples of our industry-leading work Q- Park The LightConcrete repair & coating works St Davids Dewi SantRemedial works Yoga HeroInstallation of Polyflor The Flower Bowl Entertainment CentreResin flooring Booths SupermarketReplacement and waterproofing of drainage channel Trinity MSCP, LeedsInstallation of Premium Parking Bays Browse Case Studies

- Suppliers

- Updates

- Company

case-studiesBooths Supermarket

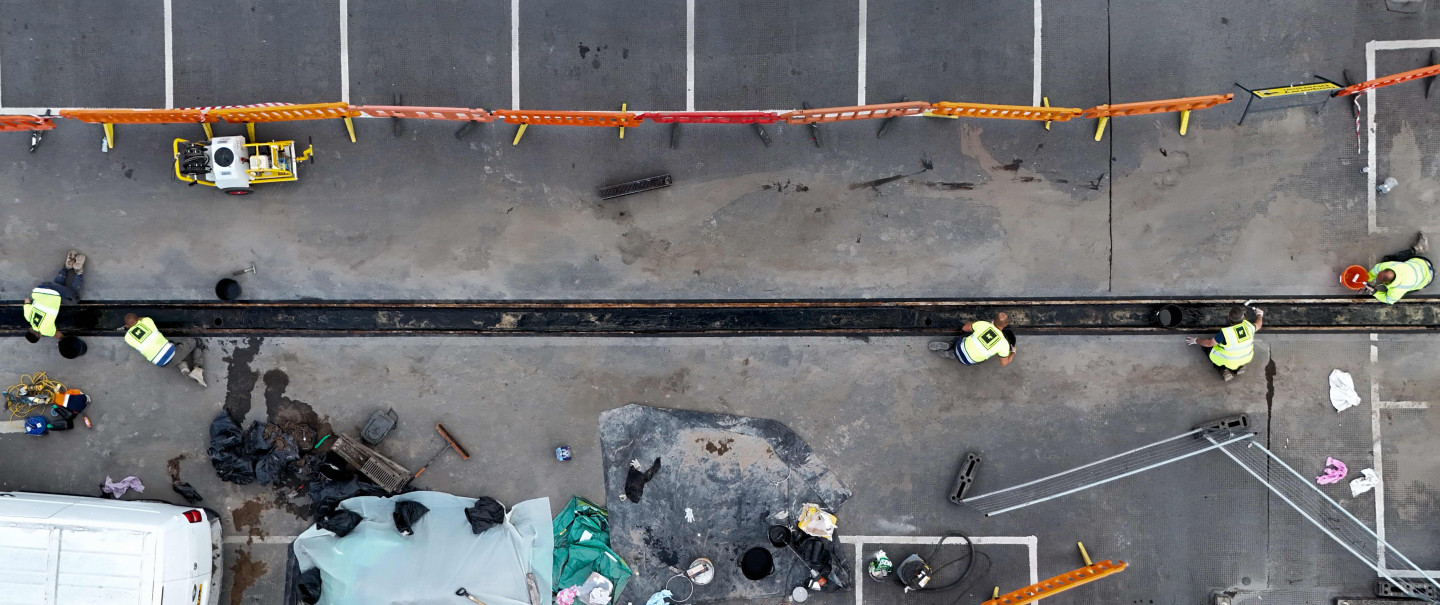

Replacement and waterproofing of drainage channel

Drainage Removal

During the removal process, we lifted the existing drainage tops and discovered that the channels were heavily blocked with silt, debris, and vegetation growth, which had been significantly restricting water flow. On closer inspection, several sections of the concrete drainage channels were found to be badly deteriorated, with parts of the structure corroded and broken away.

The existing channels were removed using a combination of pry bars, cutting equipment, and percussive tools. This ensured safe extraction of the defective sections while minimising disturbance to the surrounding asphalt surface. The removal process also allowed us to fully assess the condition of the channels and confirm the requirements for the replacement drainage to restore proper drainage performance and protect the integrity of the deck.

Defective Concrete

During the removal of the drains, we uncovered significant defects to the concrete beneath the steel beams. There was no evidence of rebar or mesh reinforcement in place under certain beam sections. This lack of reinforcement has resulted in areas of concrete becoming loose and poorly bonded, with one large section detaching after only light tapping.

To address this, we carefully chased out along each beam to create a sound, clean edge and systematically chiselled out all defective and unsound concrete. This ensured that only solid, stable material remained in place prior to the next phase of works.

Installation Preparation

Using a floor saw, we cut through the existing mastic asphalt to enable the relocation of the drainage channel, as the original installation had been incorrectly positioned. This process also allowed us to remove areas of asphalt that had deformed and risen over time due to structural movement, ensuring the surface was returned to the correct profile. In addition, the saw cutting provided clean, straight edges, which will enable a more precise reinstatement of the new drainage channel and surrounding surfacing, resulting in a stronger bond and a neat, durable finish.

Waterproofing

Once the saw cutting and removal works were complete, the exposed channel was thoroughly cleaned using a high-pressure jet wash to remove all dust, laitance, and loose debris. This ensured a sound and contaminant-free substrate for the next stage of works. After cleaning, we applied Sikafloor-151 Primer to the channel surfaces to promote adhesion and seal the substrate. Once the primer had fully cured, we installed Sikafloor Pronto 32 as a waterproofing layer within the channel. This system not only provides a robust barrier against water ingress, protecting both the new drainage installation and the underlying structure from future deterioration, but it is also highly flexible, allowing it to accommodate movement within the structure without compromising its performance. Care was taken to ensure full coverage and continuity of the waterproofing across all prepared surfaces.

Drainage Installation

We then installed the new drainage channel, carefully setting it to the correct falls to ensure efficient water flow. During the installation, we ensured that the new drainage channels were accurately aligned and securely fitted over the existing downpipes. This corrected the previous misalignment, which had contributed to poor performance, blockages, and water build-up within the system. The revised installation now provides both a precise fall and a continuous, efficient flow path, ensuring the drainage system operates effectively and as intended.

Flexible Nosing Joint

We formed a flexible nosing joint along the drainage channel using Sikafloor Pronto 32 combined with a sand dressing. This detail was designed to provide a durable yet flexible interface between the newly concreted channel and the surrounding mastic asphalt surfacing. By accommodating thermal and structural movement within the deck, the flexible nosing prevents cracking or debonding of the asphalt and avoids direct stresses being transferred onto the concreted channel edges. The joint was carefully finished to ensure a neat appearance, full bond, and a seamless transition across the surface, while also maintaining long-term protection against water ingress.

MMA Top Coat

Following the installation of the flexible nosing joint, we applied a MMA top coat in black. This final layer served two purposes: firstly, it sealed the joint to provide long-term protection against water ingress, and secondly, it created a uniform, neat finish that tied in seamlessly with the surrounding mastic asphalt surface. The use of a polyaspartic system ensures durability, UV stability, and resistance to wear from vehicle traffic, enhancing both the performance and appearance of the completed works.

services

Structural Waterproofing

Advanced structural waterproofing solutions

Preventing water ingress, and by extension structural damage to your concrete structure, is one of the most important ways of preserving the long-term life of your asset

services

Car Park Refurbishment

Extending the life of your parking structure

Refurbishment that protects both the structure and the revenue it supports.

Concrete repairs Crack injection Structural protection Deck coating Expansion joint Protection Lines & Bays Drainage Lighting

services

Structural Repairs & Protection

Concrete repairs & corrosion management

Take care of the essentials with our fast, reliable concrete repair service that ensures safety, extends structural life, and complies with industry standards